So, another small project to keep me in the game. This project, however, is needed for the restoration, not just because I thought it would be cool. This project started the restoration of the gauge cluster. Some time ago, I found a write up on changing the truck's ammeter to a voltmeter on the Stovebolt.com forum. I thought that the rationale for doing the swap that was included in the write up made good sense, so I decided that I would do it. I read that write up many times over the months, thinking through the process before actually getting the parts ready and starting.

The project itself was actually pretty easy to do. Some of the steps were kind of tedious, but all in all it went pretty quickly. Here's a shot of the gauge cluster and the ammeter before the conversion:

Given the corrosion on the exterior trim ring of the gauge cluster, I was pleasantly surprised to find the inside of the cluster free from corrosion or crud. Now, on to the conversion....

I started with a Bosch voltmeter that I got from my local FLAPS (friendly local auto parts store). It was very inexpensive, costing less than $20. It looked like this out of the box:

The first step in the conversion process is to disassemble the new voltmeter. This involves grinding the edge off the black trim ring. Once that edge is gone, you can remove the front of the trim ring. Then you have to remove the the retaining nuts on the rear of the gauge. Once the nuts are removed, the insides of the gauge can be separated from the case. The disassembled contents look like this:

In this picture, you can see the case, front trim piece, white vibration insulator, actual gauge, electrical insulator from rear of case, lock washers and retaining nuts.

The next step in the conversion is to remove the tiny screws that hold the dial face to the gauge. Jewelers screwdrivers made quick work of removing the screws. A note of caution was provided in the Stovebolt.com write up and is worth repeating here. Those tiny screws go into tiny plastic screw bosses. Over tightening them will break those bosses. Here's a pic of the dial face and screws once they were removed:

I included the jeweler's screwdriver for size reference. Here's a shot of the gauge after dial face removal:

Another note of caution: Notice the thin wire wrapped around the dial face screw bosses? It is a very thin wire and appears that it would be easily damaged. In this pic, I'm test fitting the gauge in the gauge cluster. The gauge would need trimming before it would fit properly. This was expected, based on the Stovebolt.com article. Here are some shots showing why it needed the trim.

Notice the gap between the case and the cluster trim ring?

And on the rear, the gauge's insulators protrude just a little too far and need to be trimmed down a bit. The trimming is a 2 step process where you have to trim both the edge that is visible and the little ledge that keeps the gauge from contacting the cluster mount. That is an awkward description, hopefully this pic, together with the one above will help explain better than I can.

In this shot, you can see the parts of the gauge that keep the actual gauge from contacting the metal of the cluster mount. The other reason that you need to trim these plastic pieces is shown in the next pic. It shows that the needle contacts the cluster trim ring without doing the trimming.

After the trimming, everything fit just fine. It looked like this:

And this:

While it looks like there is still a gap between the case and the trim ring, it isn't because of interference between the gauge and/or needle and the trim.

The next bit of adjustment is to the original gauge face. The original face had 2 dimples punched into it where it was riveted to the original gauge. The gauge face, once removed, looked like this:

and this:

The problem with the dimples was that it interfered with the needle. This is evident from this pic:

Also, the rivet holes were not in the right location for the screws to fit into the new gauge frame. So, I had to flatten the dimples and measure and drill new holes. Once flattened, the gauge face looked like this:

It's a little hard to see, but if you look hard, you can see the black dots where the new holes need to go. I used the new gauge face as a template for locating the holes on the old face plate. One other adjustment to the gauge face that you can kind of see is that the opening that surrounds the needle had to be enlarged. That was done with the Dremel and cut-off wheel. In actuality, the trimming was done before the dimples were flattened. You can see that in this pic, the trimming has been done, but the dimples remain:

Anyway, once all of that was done, I assembled the old gauge face to the new gauge and it looked like this:

The guts from the original gauge are next to the new one. I included the guts from the old gauge to highlight the one real telltale sign of the change. The old gauge reads zero when it's not energized, which is in the middle of the gauge. The new one goes to zero, which is all the way to the left. A subtle difference, but different for sure. We'll see who notes it if I ever get the truck back on the road. Another slight adjustment was painting the needle from the original red, to a more correct white. For this, I just used what I already had on hand, which was Rustoleum flat white.

So, at this point, it looks pretty good...but does it work? Only one way to find out. So, I used some test leads and hooked it up to the engine test stand car battery. It's a normal car battery, connected to a trickle charger. The gauge performed like this:

If you remember from the pic of the original Bosch gauge face, 13 volts is the midway point of that gauge and the zero is the midway point of the original gauge. So, this gauge is reading about 12 volts on my battery connected to the trickle charger. With the engine running, I would expect it to read just above the zero, indicating about 14 volts. Pretty straightforward. Here it is in the original gauge cluster frame:

Here it is connected to the battery, still showing about 12 volts, which shows that the electrical connections are good and separated. Here's a shot of the back, with the insulator in place:

If you enlarge the pic, you can see that Bosch was nice enough to emboss the (+) and (-) on the insulator. Thanks, Bosch! Of course, you do have to orient them in the correct position or the gauge will read backwards!

So that's it! The ammeter is gone, replaced with a voltmeter. The risk of burning my truck to the ground is greatly reduced. Now, I have to address each of the other gauges. I think that I'm going to use a voltage reducer for the gas gauge and retain the original oil pressure gauge. The only wildcard right now is the water temp gauge. I kind of bollixed up that one when I was taking the gauge cluster out of the dash. So I either have to buy an original one and hope that it works or buy a new one. Maybe I'll look into moving the original gauge face onto a newly manufactured gauge. We'll see....

All about working on and restoring my 1953 Chevy 3100 (1/2 ton) pickup truck including the inline 6 235 engine

1953 chevy truck ad

Tuesday, October 4, 2016

Tuesday, August 30, 2016

Old Chevy Blue for the New Water Pump

Earlier this summer, I found out that the water pump that came on the junkyard engine had given up the ghost. It was squealing and leaking when I started the engine. I bought a new, short shaft one almost immediately after discovering the need. However, it was summer and the heat and humidity made it almost impossible to do any real work in the garage. So it sat and waited for me. I knew that I'd have to paint it, as it came from the online retailer in bare cast iron and looked like this:

You know it couldn't possibly go in the truck like that. It would take all of a day before it was completely rusted. In this pic, you can see a bit of wadded up newspaper sticking out of the heater hose connection points. This was to keep paint out of the inside of the pump. Since the anti-freeze has rust inhibitors in it, I figured no paint on the inside. So the underside got masking tape and looked like this:

The area that I masked off included the area that will get the gasket. I guess I could have painted that and the gasket would have adhered just fine, at the time, I went for masking.

Then, I used the Duplicolor VHT primer and paint. For the paint color, I went with Old Chevy Blue, as that is the color of the junkyard engine. As you may recall, the engine came out of a 1961 Chevy Impala and is a 235 inline 6. That engine was painted Chevy blue from the factory, so instead of trying to hide it by painting the engine Chevy gray like an original 1953 engine would be painted, I am celebrating the origin of the junkyard engine. So, Chevy blue it is. Here's a shot of the water pump while drying in the garage:

The lighting is a little weird, so the color looks a little washed out in this pic, but looks much better in this next pic, which shows the underside of the pump with the masking tape removed. It looks like this:

So there it is, ready to be installed. On a side note, the pump was purchased from Jim Carter Trucks. I was a little bummed that it came in bare cast iron with no paint or primer to keep it from rusting. However, I was pleased to see that it came with the appropriate gasket and 2 plugs for the heater hose openings. If I choose to hook up a heater, I would use the correct heater hose nipples. If I don't want to hook up a heater right away, I can use the plugs. Right now, I have not refurbished the heater core, so the plugs will go in initially. Later, when I refurbish the heater core, I'll swap out the plugs for the nipples. Piece of cake.

That's all for now.

You know it couldn't possibly go in the truck like that. It would take all of a day before it was completely rusted. In this pic, you can see a bit of wadded up newspaper sticking out of the heater hose connection points. This was to keep paint out of the inside of the pump. Since the anti-freeze has rust inhibitors in it, I figured no paint on the inside. So the underside got masking tape and looked like this:

The area that I masked off included the area that will get the gasket. I guess I could have painted that and the gasket would have adhered just fine, at the time, I went for masking.

Then, I used the Duplicolor VHT primer and paint. For the paint color, I went with Old Chevy Blue, as that is the color of the junkyard engine. As you may recall, the engine came out of a 1961 Chevy Impala and is a 235 inline 6. That engine was painted Chevy blue from the factory, so instead of trying to hide it by painting the engine Chevy gray like an original 1953 engine would be painted, I am celebrating the origin of the junkyard engine. So, Chevy blue it is. Here's a shot of the water pump while drying in the garage:

The lighting is a little weird, so the color looks a little washed out in this pic, but looks much better in this next pic, which shows the underside of the pump with the masking tape removed. It looks like this:

So there it is, ready to be installed. On a side note, the pump was purchased from Jim Carter Trucks. I was a little bummed that it came in bare cast iron with no paint or primer to keep it from rusting. However, I was pleased to see that it came with the appropriate gasket and 2 plugs for the heater hose openings. If I choose to hook up a heater, I would use the correct heater hose nipples. If I don't want to hook up a heater right away, I can use the plugs. Right now, I have not refurbished the heater core, so the plugs will go in initially. Later, when I refurbish the heater core, I'll swap out the plugs for the nipples. Piece of cake.

That's all for now.

Saturday, July 2, 2016

Steering Always Makes a Kid Smile

It always made me smile. Although I wasn't steering the truck down the road, I still couldn't help but smile when I grabbed the restored wheel for the first time.

To truly enjoy the video the way I intended, go to youtube and load "Carryon Wayward Son" by Kansas, hit the play button there, then hit the play button here. Those of you who are familiar with Supernatural will get the connection. Enjoy:

The Road So Far

To truly enjoy the video the way I intended, go to youtube and load "Carryon Wayward Son" by Kansas, hit the play button there, then hit the play button here. Those of you who are familiar with Supernatural will get the connection. Enjoy:

The Road So Far

The Gray Ghost Goes Tinkle...In A Bad Sort Of Way

Well, I decided to fire up the replacement engine today with the hope of running an oil cleaner solution through the engine and then doing an oil change. The oil that is in the engine is oil that I put in after getting the engine from the junkyard. It's been in there a while and needs to be changed. Additionally, I'm sure it has collected all of the sludge that was normal back in the day before detergent oils. Since this is a new oil and likely has detergent (I really can't remember if it does or does not, so I'm assuming that it does) it will cause the sludge to go back into suspension where it could cause damage to the engine. So, I figured a good cleaner, followed by an oil change would be a good thing to do on a Saturday morning.

I got the engine out from where I store it in the garage and notice a wet looking spot on the floor. It was not something that I had ever seen before, so it was worrisome, but I preceded on with prepping the engine for a run.

Since the engine had been sitting for a couple of months since it's last run, I knew it would take a few tries to get it to fire. Sure enough, it took several tries to get gasoline to the carb and for the intake manifold to have enough fuel vapor in it to fire the engine. But we got there. As soon as we did, I heard the squeal.... You know the one, where you hope it is the belt and not the bearings of your water pump, but deep down inside you know it's the water pump. Sure enough, I looked around at the pump and found this:

And this:

Party over. I guess it's not surprising, given the age of the engine and the water pump. I knew I was going to need a replacement to change to the short shaft variety, but figured I had time before doing that. So, time to save up some money and get the right water pump.

That's all for now.

Friday, June 24, 2016

The Gray Ghost Borders are now Less Secure...Maybe?!?

Just a quick note to let everyone know that I've removed the automatic HTTP to HTTPS redirect. The photo website that I use (photobucket) does not support HTTPS and my photo slideshow would not show on my blog. The photos are a huge part of the experience that I want to create, so not having the slideshow was unacceptable. I struggled for several days, trying to figure out how to make them show, without abandoning photobucket and redoing all of the links in all of my posts. I suppose I could just leave the old posts alone and photobucket alone and start from this post forward and use a different photo site, but that is a ton of work, that I feel is unnecessary.

So, if you load the blog and do not get the photo slideshow on the right, reload it in HTTP and the slideshow should appear. If it does not, please leave a comment so that I can try to fix it.

I'll let everyone know what the final resolution to the problem is.

For now, how about a random pic to whet the appetite?

Of course, it's not really a pic of the truck. It's a scan of the datasheet for my truck model, highlighted for your reading pleasure. Enjoy.

So, if you load the blog and do not get the photo slideshow on the right, reload it in HTTP and the slideshow should appear. If it does not, please leave a comment so that I can try to fix it.

I'll let everyone know what the final resolution to the problem is.

For now, how about a random pic to whet the appetite?

Sunday, May 22, 2016

Steering Through Life's Mysteries or the Wheel of Restoration

In keeping with my theme of doing some level of restoration on the interior of the truck, while leaving the exterior kinda of ratty, I removed the steering wheel from the steering column. This will enable me to do a thorough restoration of the actual steering wheel and give me better access to the dash and the steering column. I will sand down the rust and crusty primer and then prime and rattle can paint each. According to many posts on the truck forum that I belong to, the Rustoleum color #7272 is a very close match to the original dash color. I'll get some of that in the future, when I'm ready to paint the dash. The steering column appears to have been some color of gray. I'll do some digging on the forum to see if there is a modern equivalent. But for now, my attention is on the wheel.

As a reminder, here is how the steering wheel looked while it was in the truck:

Here is how it looked when I got it out and onto the workbench.

Front:

Back:

A couple of things to take away from these shots, other than the messy workbench:

1. The steering wheel has many cracks in it.

2. The wrap has worn away in many places.

3. The wheel has areas with no paint, some original paint, some primer and some other paint drips.

4. A lot of dirt and grime in the area where the horn button sits.

After getting the wheel onto the bench and taking those before pics, I set about trying to get that green wrap off of the wheel. It had clearly been there for a very long time! So long, in fact, that some areas (as noted in #2 above) had actually been worn away. So you might think that it would be pretty easy to just pick at it and flake it off or peel it off in big pieces. Well, not so much. Apparently, this was the top of the line steering wheel wrap back in the day. It had some kind of adhesive on it. Which means that what was left of it was still very much stuck to the wheel and where there wasn't any wrap left, there was glue. OMG! Like everything else so far, what should be an easy job becomes a bit of a chore. Any way, armed with a small pick, I started flaking away the wrap, working my way around the wheel. It took about 1 1/2 to 2 hours to work my way around. When I was done, this is what I had:

Can you see the small little flakes?!? Yes, there are some large curls of wrap, but can you see the small flakes?!? Also in the top right you can see a can of Goof Off. It was moderately effective at loosening the glue's hold on the wrap and allowed me to get the pick under an edge without damaging the steering wheel material. What I was left with, though, was a spiral outline of the wrap. At first, I thought the wrap had actually molded the steering wheel material. But when I looked closer, the spiral outline was all the glue that was left on the wheel.

Well, you can't paint over glue, so I got the Goof Off out again and went at it. First scraping glue with the pick and then wiping with the Goof Off. It was pretty slow going, so I switched to acetone. The acetone was much more effective than the Goof Off, even though the Goof Off smelled much stronger. Since the wrap covered all sides of the wheel where it was applied, I have to wipe with the acetone all sides of the wheel. Unfortunately, even with the acetone, the glue does not come up completely on the first pass. I spent another couple of hours working the pick and then wiping with the acetone until I needed a fresh air break (yes even with the garage door open, the fumes were pretty bad).

Before I took the break, I did do some mild sanding with a 220 grit sanding block. Some of the areas of the wheel looked as though there was some kind of a build up on it. I didn't know what it was, but decided I wasn't going to paint over it, so it had to go.

Here is a before and after shot after picking, scraping, wiping and sanding:

Before:

After:

It's easy to see the spiral glue marks in the before pic, especially if you click on it and enlarge it. The glue marks are lessened and in some cases gone in the after pic. Clearly, I am not done with this phase of the effort. But brain preservation dictated a break....

Here is a close up of one of the wheel spokes. Because the wrap covered this area completely, the original paint was preserved. It was good to find some of the original paint, as it takes all of the guesswork out of deciding what color to paint the wheel. Here's the closeup:

This shot really shows it all. Here you can clearly see the primer (which ran when it was sprayed on...) the original paint, the wheel material, the glue and where I've scraped at it and the remnants of the glue spirals.

Here is a closeup of the worst cracked area. I'm going to use the epoxy putty to fill this in, once I've gotten it all cleaned out. Here's the crack closeup:

It looks pretty bad. Hopefully, the epoxy putty will do the trick. If not, then I'll have to replace the wheel. I'm really hopeful that I can fix it and save the wheel.

That's all for now. That's as far as I've gotten. I wanted to do this update, as the next phase will take me a while to complete.

Don't forget to vote in the test poll from my last post! Not many of you have voted...and I know that you're out there. So get out there people and vote! Please.

As a reminder, here is how the steering wheel looked while it was in the truck:

Here is how it looked when I got it out and onto the workbench.

Front:

Back:

A couple of things to take away from these shots, other than the messy workbench:

1. The steering wheel has many cracks in it.

2. The wrap has worn away in many places.

3. The wheel has areas with no paint, some original paint, some primer and some other paint drips.

4. A lot of dirt and grime in the area where the horn button sits.

After getting the wheel onto the bench and taking those before pics, I set about trying to get that green wrap off of the wheel. It had clearly been there for a very long time! So long, in fact, that some areas (as noted in #2 above) had actually been worn away. So you might think that it would be pretty easy to just pick at it and flake it off or peel it off in big pieces. Well, not so much. Apparently, this was the top of the line steering wheel wrap back in the day. It had some kind of adhesive on it. Which means that what was left of it was still very much stuck to the wheel and where there wasn't any wrap left, there was glue. OMG! Like everything else so far, what should be an easy job becomes a bit of a chore. Any way, armed with a small pick, I started flaking away the wrap, working my way around the wheel. It took about 1 1/2 to 2 hours to work my way around. When I was done, this is what I had:

Can you see the small little flakes?!? Yes, there are some large curls of wrap, but can you see the small flakes?!? Also in the top right you can see a can of Goof Off. It was moderately effective at loosening the glue's hold on the wrap and allowed me to get the pick under an edge without damaging the steering wheel material. What I was left with, though, was a spiral outline of the wrap. At first, I thought the wrap had actually molded the steering wheel material. But when I looked closer, the spiral outline was all the glue that was left on the wheel.

Well, you can't paint over glue, so I got the Goof Off out again and went at it. First scraping glue with the pick and then wiping with the Goof Off. It was pretty slow going, so I switched to acetone. The acetone was much more effective than the Goof Off, even though the Goof Off smelled much stronger. Since the wrap covered all sides of the wheel where it was applied, I have to wipe with the acetone all sides of the wheel. Unfortunately, even with the acetone, the glue does not come up completely on the first pass. I spent another couple of hours working the pick and then wiping with the acetone until I needed a fresh air break (yes even with the garage door open, the fumes were pretty bad).

Before I took the break, I did do some mild sanding with a 220 grit sanding block. Some of the areas of the wheel looked as though there was some kind of a build up on it. I didn't know what it was, but decided I wasn't going to paint over it, so it had to go.

Here is a before and after shot after picking, scraping, wiping and sanding:

Before:

After:

It's easy to see the spiral glue marks in the before pic, especially if you click on it and enlarge it. The glue marks are lessened and in some cases gone in the after pic. Clearly, I am not done with this phase of the effort. But brain preservation dictated a break....

Here is a close up of one of the wheel spokes. Because the wrap covered this area completely, the original paint was preserved. It was good to find some of the original paint, as it takes all of the guesswork out of deciding what color to paint the wheel. Here's the closeup:

This shot really shows it all. Here you can clearly see the primer (which ran when it was sprayed on...) the original paint, the wheel material, the glue and where I've scraped at it and the remnants of the glue spirals.

Here is a closeup of the worst cracked area. I'm going to use the epoxy putty to fill this in, once I've gotten it all cleaned out. Here's the crack closeup:

It looks pretty bad. Hopefully, the epoxy putty will do the trick. If not, then I'll have to replace the wheel. I'm really hopeful that I can fix it and save the wheel.

That's all for now. That's as far as I've gotten. I wanted to do this update, as the next phase will take me a while to complete.

Don't forget to vote in the test poll from my last post! Not many of you have voted...and I know that you're out there. So get out there people and vote! Please.

Sunday, May 15, 2016

Poll Test v2.0 (Revised Poll)

Hi Everybody,

I'm working on a new post and I want to include a real poll in it to get your feedback. Google, by way of Blogger, doesn't make it easy to put polls into individual blog posts. Instead, they want you to put it in your layout. That would make it appear in every post.... Not the best approach, unless you wanted to keep the data generated by the poll and then mine it for...wait for it...MONEY!

I did some research and think that I've found a way to do it. It seems straightforward, but involves switching from the GUI that blogger uses to the html interface. I'm not really conversant in html, so it could be a challenge.

So, in order to test my polling prowess, or my html prowess or both, I've come up with a silly poll to see if it works. (I can't see the poll in the preview mode, so I'll have to go live with the post to see.) The poll is below, but first a couple of requests:

1. Please try to fill out the poll. It is only 1 question with a couple of possible answers. Just pick 1 answer.

2. If for some reason, you can't see the poll or it doesn't work, please leave a comment that specifies what went wrong.

I need that feedback, because the next poll will allow you, the reader, to help me decide on a part of the Gray Ghost that I'm going to work on next! I've got the part already picked out, but could do it in 2 different ways. I'm going to let you help me decide!

So for now, the test poll (OBTW, it anonymous!)

I'm working on a new post and I want to include a real poll in it to get your feedback. Google, by way of Blogger, doesn't make it easy to put polls into individual blog posts. Instead, they want you to put it in your layout. That would make it appear in every post.... Not the best approach, unless you wanted to keep the data generated by the poll and then mine it for...wait for it...MONEY!

I did some research and think that I've found a way to do it. It seems straightforward, but involves switching from the GUI that blogger uses to the html interface. I'm not really conversant in html, so it could be a challenge.

So, in order to test my polling prowess, or my html prowess or both, I've come up with a silly poll to see if it works. (I can't see the poll in the preview mode, so I'll have to go live with the post to see.) The poll is below, but first a couple of requests:

1. Please try to fill out the poll. It is only 1 question with a couple of possible answers. Just pick 1 answer.

2. If for some reason, you can't see the poll or it doesn't work, please leave a comment that specifies what went wrong.

I need that feedback, because the next poll will allow you, the reader, to help me decide on a part of the Gray Ghost that I'm going to work on next! I've got the part already picked out, but could do it in 2 different ways. I'm going to let you help me decide!

So for now, the test poll (OBTW, it anonymous!)

Friday, May 6, 2016

Securing The Gray Ghost Borders And Checking A Box

Hi All,

Just a quick note to let you know that Blogger has changed the settings for the website. The URL now includes "https" instead of just "http". If you use the old "http" you will get a redirect to the new address. So, if you've bookmarked the old address, you should update the bookmark.

On a different note, I've added a feature at the bottom of my posts. It's a set of check boxes to like, dislike, etc my posts. I'm just short of 1,000 page views and have only received a handful of comments. Clearly my audience is shy or my posts are boring.... I thought this would be a quick way to get some feedback, so come on readers and Gray Ghost fans: check a box!

Here's a previously unpublished pic of the Gray Ghost to get you motivated!

Of course, its the heater! I'll be taking it out and doing a restoration on it. This style of heater uses a unique circular heater core. It has 2 semi-circular halves that are soldered together with an inlet hose on one half and and outlet on the other. There are some companies that refurbish these cores, but I think I'm going to use a new product that fits the same space (is circular) but is one piece and includes a 12v blower motor. Most importantly, it's the same price as refurbing the old one. Sounds like a win-win. Now I just have to get the funds together.... Story of my restoration life.

Just a quick note to let you know that Blogger has changed the settings for the website. The URL now includes "https" instead of just "http". If you use the old "http" you will get a redirect to the new address. So, if you've bookmarked the old address, you should update the bookmark.

On a different note, I've added a feature at the bottom of my posts. It's a set of check boxes to like, dislike, etc my posts. I'm just short of 1,000 page views and have only received a handful of comments. Clearly my audience is shy or my posts are boring.... I thought this would be a quick way to get some feedback, so come on readers and Gray Ghost fans: check a box!

Here's a previously unpublished pic of the Gray Ghost to get you motivated!

Of course, its the heater! I'll be taking it out and doing a restoration on it. This style of heater uses a unique circular heater core. It has 2 semi-circular halves that are soldered together with an inlet hose on one half and and outlet on the other. There are some companies that refurbish these cores, but I think I'm going to use a new product that fits the same space (is circular) but is one piece and includes a 12v blower motor. Most importantly, it's the same price as refurbing the old one. Sounds like a win-win. Now I just have to get the funds together.... Story of my restoration life.

Friday, April 8, 2016

Light Down the Rabbit Hole

A funny thing happened when I was searching for mounting brackets for my restored backup lights. I found a really nice pair of Dietz Model 909 driving lights. The lights are pretty old, but I'm not sure exactly how old. They are very sturdy and made out of very thick metal, which made restoration pretty easy. I started work on the light that was the rustiest. I started by disassembling the light assembly. The bulb is held in the light by a ring on the outside and pinched together by a nut and bolt. Remove the nut an bolt and sort of peel the ring off of the housing. The bulb then easily comes out. The electrical connections are made by two slip on connectors that attach to screws on the back of the bulb. Initially, the ground connection is through the bulb housing. This was really rusty and I decided that I would use two wires to the outside of the housing, similar to how I wired the backup lights. Later, if I want to do a frame off restoration of the truck, I'll do the same for the Dietz lights and re-establish the internal ground. But for now, I'll just ground through an external connection. Here is a shot of the inside before restoration:

In this shot, you an see some overspray from when I painted the outside. I did one side at a time, although if I were using a media blaster, I would do both sides at once. But since I was doing it by hand, I did one side at a time. In this pic you an also see the clip on the right side. This is for a tab molded in the glass bulb that holds the bulb in one position and keeps it from spinning around while it is bouncing down the road. You can also see the old ground connection. I cut that out. For the full restoration, I would grind off the rivets and separate the mounting part from the housing. This would give me the opportunity to add a new ring connector for the internal ground. That is some time down the road however.

Here is a shot of the restored and new parts:

You can see the restored interior. Although I used a self etching primer, it didn't quite match the original color, but it is green like the original. The nut and bolt that pinched the ring together had to be replaced. The new one is stainless steel, so hopefully it won't rust. The ring was also stripped then primed and painted. The bulb is a 12 volt replacement (model 4412) and is really a tractor light, but it is the replacement for the 6v bulb (model 4012).

Here is a shot of the exterior of the housing and other parts:

The exterior of the housing was stripped of rust and then primed and painted. The painting turned out to be a weird adventure. I had bought a can of gray spray paint last fall for use on the steering column. I didn't get to that last fall, so I decided I would use it on the lights. When I tried to use it, blobs of paint shot out of the can! I was really dejected, because it meant sanding it down and starting over. However, when I looked at it closely, it looked like I could knock down the high spots and just paint over it with a new can of paint. When I did that, it looked like a heavy duty textured paint like one you would see on industrial equipment. I loved it! So, the other light will get the same treatment! In this pic, you can see the screw tabs on the light bulb for attaching the electrical leads. You can also see the bolt that attached the light housing to the mounting bracket. This bolt looked a little buggered up when I got the light, but I chased the threads and it turned out to be fine. I added a new stainless lock washer and nut and it is good to go. For the wiring, I got 12 gauge wires and made each lead a 5 foot lead. That way, I would be sure to have enough wire to reach when I installed the lights.

Here is a side shot of the housing after final assembly:

Fitting 2 12 gauge wires through the small grommet was difficult, but doable. I had to put the wires through the grommet, then install the grommet into the housing, but it worked.

Here is a front shot of the light after assembly:

I did test the functionality of the light after assembly and it worked fine. I didn't take a pic of that...not enough hands.

Here is a shot of the mounting brackets that I will use for these driving lights:

It is clear from the pic that these are 2 different brackets. However, you can also see that even though the shape of the brackets is different, they end up at the same height. So for now, I'm going with them. I'll keep an eye out for one of the top pieces that matches either one, doesn't really matter which one. Ultimately, I want to get these blasted and powder coated, but that may be down the road a bit. It is really amazing to me just how heavy duty these brackets are and how heavy they are. But in a test fit on the bumper, they seem to just suck down on the bumper. I have no doubt that they'll hold fast and tight when I snug down the nuts and bolts.

So, how about those backup lights? Well, I found a different set of brackets for those lights! It is a nice pair of chromed brackets that are smaller than these brackets and look like NOS. Gotta love those rabbit holes! You never know where they'll lead you!

In this shot, you an see some overspray from when I painted the outside. I did one side at a time, although if I were using a media blaster, I would do both sides at once. But since I was doing it by hand, I did one side at a time. In this pic you an also see the clip on the right side. This is for a tab molded in the glass bulb that holds the bulb in one position and keeps it from spinning around while it is bouncing down the road. You can also see the old ground connection. I cut that out. For the full restoration, I would grind off the rivets and separate the mounting part from the housing. This would give me the opportunity to add a new ring connector for the internal ground. That is some time down the road however.

Here is a shot of the restored and new parts:

You can see the restored interior. Although I used a self etching primer, it didn't quite match the original color, but it is green like the original. The nut and bolt that pinched the ring together had to be replaced. The new one is stainless steel, so hopefully it won't rust. The ring was also stripped then primed and painted. The bulb is a 12 volt replacement (model 4412) and is really a tractor light, but it is the replacement for the 6v bulb (model 4012).

Here is a shot of the exterior of the housing and other parts:

The exterior of the housing was stripped of rust and then primed and painted. The painting turned out to be a weird adventure. I had bought a can of gray spray paint last fall for use on the steering column. I didn't get to that last fall, so I decided I would use it on the lights. When I tried to use it, blobs of paint shot out of the can! I was really dejected, because it meant sanding it down and starting over. However, when I looked at it closely, it looked like I could knock down the high spots and just paint over it with a new can of paint. When I did that, it looked like a heavy duty textured paint like one you would see on industrial equipment. I loved it! So, the other light will get the same treatment! In this pic, you can see the screw tabs on the light bulb for attaching the electrical leads. You can also see the bolt that attached the light housing to the mounting bracket. This bolt looked a little buggered up when I got the light, but I chased the threads and it turned out to be fine. I added a new stainless lock washer and nut and it is good to go. For the wiring, I got 12 gauge wires and made each lead a 5 foot lead. That way, I would be sure to have enough wire to reach when I installed the lights.

Here is a side shot of the housing after final assembly:

Fitting 2 12 gauge wires through the small grommet was difficult, but doable. I had to put the wires through the grommet, then install the grommet into the housing, but it worked.

Here is a front shot of the light after assembly:

I did test the functionality of the light after assembly and it worked fine. I didn't take a pic of that...not enough hands.

Here is a shot of the mounting brackets that I will use for these driving lights:

It is clear from the pic that these are 2 different brackets. However, you can also see that even though the shape of the brackets is different, they end up at the same height. So for now, I'm going with them. I'll keep an eye out for one of the top pieces that matches either one, doesn't really matter which one. Ultimately, I want to get these blasted and powder coated, but that may be down the road a bit. It is really amazing to me just how heavy duty these brackets are and how heavy they are. But in a test fit on the bumper, they seem to just suck down on the bumper. I have no doubt that they'll hold fast and tight when I snug down the nuts and bolts.

So, how about those backup lights? Well, I found a different set of brackets for those lights! It is a nice pair of chromed brackets that are smaller than these brackets and look like NOS. Gotta love those rabbit holes! You never know where they'll lead you!

Friday, February 19, 2016

Cue The Mission Impossible Music

I had a little time today, so I decided to remove the passenger side park light. It was rusted in place, so both bolts broke off while I was trying to remove the nuts. Turns out the whole thing is really rusty and I'm not sure I can save it. Here it is after removing it from the truck:

I think that everyone will agree that this is rusty! Instead of trying to go straight into the Evap-O-Rust, I decided to cut off the rivets and separate the bar from the housing and disassemble the all of the parts, then give them a soak. Here is an exploded view of all of the parts front and back:

The funny thing that you can clearly see in the last 2 pics is the gray primer that the previous owner sprayed on everything (think back to the primered pencils and cigarette butts in the ashtray) is covering the outside of the glass lens. That is why it looks kind of frosted or milky. But when you look at the inside, it is nice and clear. Thankfully, it comes off easily and is way less of a concern than the state of the metal housing. I think that the bar is shot, so I'm going to attempt to make one over the weekend. The front bezel and gasket are also shot and will need to be replaced. If this doesn't work out, I may try to find a decent one online, if the prices aren't too high.

Currently the housing and bar are soaking...we'll see.

Here's a top view (that will not allow me to rotate it into a normal view...Photobucket strikes again):

I think that everyone will agree that this is rusty! Instead of trying to go straight into the Evap-O-Rust, I decided to cut off the rivets and separate the bar from the housing and disassemble the all of the parts, then give them a soak. Here is an exploded view of all of the parts front and back:

The funny thing that you can clearly see in the last 2 pics is the gray primer that the previous owner sprayed on everything (think back to the primered pencils and cigarette butts in the ashtray) is covering the outside of the glass lens. That is why it looks kind of frosted or milky. But when you look at the inside, it is nice and clear. Thankfully, it comes off easily and is way less of a concern than the state of the metal housing. I think that the bar is shot, so I'm going to attempt to make one over the weekend. The front bezel and gasket are also shot and will need to be replaced. If this doesn't work out, I may try to find a decent one online, if the prices aren't too high.

Currently the housing and bar are soaking...we'll see.

Wednesday, February 17, 2016

The Dangers of Hidden Rust: De-Rusting Part 3

Well, I couldn't leave it alone. I just knew that the Evap-O-Rust wasn't getting all of the rust. So, armed with drill bits and small punches, I set about removing the bar from the bottom of the park light housing. Here is the whole housing before de-rusting in the Evap-O-Rust:

Admittedly, it was pretty rusty and gnarly. Now, here it is after the initial soak in the Evap-O-Rust and polishing with the Dremel and a light abrasive wheel:

Even after the soak and polishing, you can see the pits are still dark colored (probably rusty) and I was convinced that there was rust between the bar and the main housing. They say a picture is worth a thousand words so here goes with a pic after drilling and punching the rivets out:

And there you have it: RUST! Hidden from view and survived a 24 hour soak in the Evap-O-Rust. Right now, it is back in for another soak. When it comes out, I'll polish it again and see how the pits are and if the bar is salvageable. If it is, I'll look into getting replacement bolts. If not, I'll try my hand at making a replacement strap. It's hard to see, but there is a subtle bend on each end to accommodate the bolts, which are specialty bolts. In a quick search online, it appears that these bolts are called "elevator bolts". They fit the description of elevator bolts, anyway. If I end up making a new bar, I may make the bend a little more pronounced to accommodate regular carriage bolts, which have a slightly thicker head. No matter which way I go, I'll pop rivet them back onto the housing. So far, it looks like I should be able to salvage these housings. I'll keep you posted on the progress.

Admittedly, it was pretty rusty and gnarly. Now, here it is after the initial soak in the Evap-O-Rust and polishing with the Dremel and a light abrasive wheel:

Even after the soak and polishing, you can see the pits are still dark colored (probably rusty) and I was convinced that there was rust between the bar and the main housing. They say a picture is worth a thousand words so here goes with a pic after drilling and punching the rivets out:

And there you have it: RUST! Hidden from view and survived a 24 hour soak in the Evap-O-Rust. Right now, it is back in for another soak. When it comes out, I'll polish it again and see how the pits are and if the bar is salvageable. If it is, I'll look into getting replacement bolts. If not, I'll try my hand at making a replacement strap. It's hard to see, but there is a subtle bend on each end to accommodate the bolts, which are specialty bolts. In a quick search online, it appears that these bolts are called "elevator bolts". They fit the description of elevator bolts, anyway. If I end up making a new bar, I may make the bend a little more pronounced to accommodate regular carriage bolts, which have a slightly thicker head. No matter which way I go, I'll pop rivet them back onto the housing. So far, it looks like I should be able to salvage these housings. I'll keep you posted on the progress.

Sunday, February 14, 2016

De-Rusting Part 2

Well, it's been a little more than 24 hours and the Evap-O-Rust results are in. Here are the before and after shots:

Plus a couple shots from different angles after a quick polishing with the Dremel:

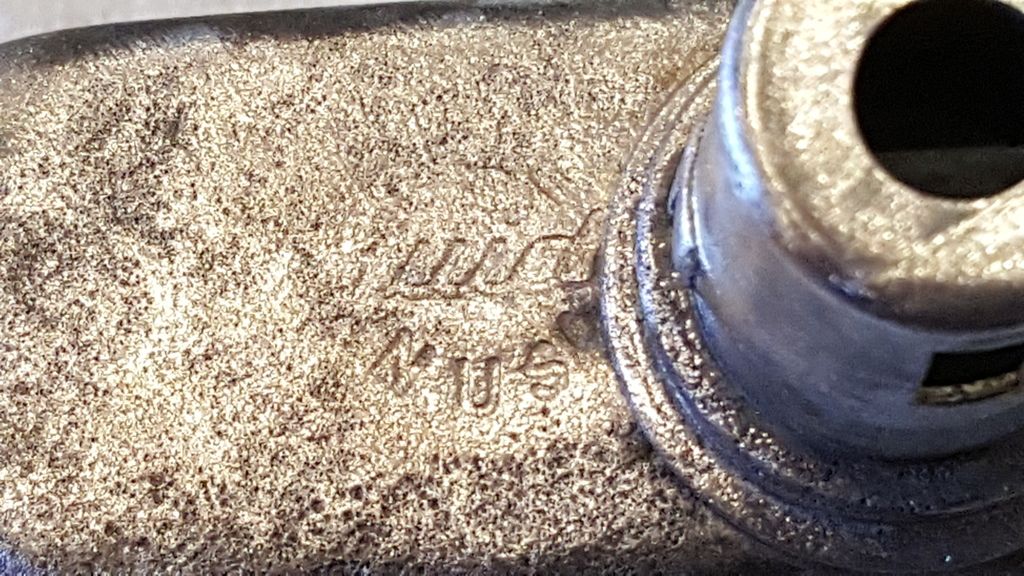

On this shot, you can make out the "Guide" maker's mark and part of the "Made in USA". But, you can also see just how pitted the metal is from the corrosion. The pitting doesn't go all the way through and will not be seen, since it is on the back of the housing. So I think it is salvageable from that perspective. I am thinking, however, that I will drill out the rivets that hold the bracket with the bad bolts and remove the bracket. Removing the bracket will allow me to fully clean underneath it and install new bolts. Then I can reattach the bracket to the housing, probably with pop rivets.

When I remove the bracket and do that part of the housing restoration, I'll post on that plus the painting and rebuilding of the unit. Also, I plan to do the passenger side light, too.

In the final "analysis", the Evap-O-Rust did a great job cutting through the rust. It wasn't able to get down into the pits, but I think it would have if I had left it in the solution for a couple of days longer. You may be able to see the difference between the straight out of the solution look and the look after polishing. When the metal comes out of the tank, it has a dull gray look to it. I used the Dremel and a high number (light grit) wheel and polished the gray off. It would now be ready for primer, if I wasn't going to remove the bracket and replace the bolts. If I do that soon, I should be able to avoid surface rusting. If some does show up, then I'll polish it again and then prime. See you then....

Plus a couple shots from different angles after a quick polishing with the Dremel:

On this shot, you can make out the "Guide" maker's mark and part of the "Made in USA". But, you can also see just how pitted the metal is from the corrosion. The pitting doesn't go all the way through and will not be seen, since it is on the back of the housing. So I think it is salvageable from that perspective. I am thinking, however, that I will drill out the rivets that hold the bracket with the bad bolts and remove the bracket. Removing the bracket will allow me to fully clean underneath it and install new bolts. Then I can reattach the bracket to the housing, probably with pop rivets.

When I remove the bracket and do that part of the housing restoration, I'll post on that plus the painting and rebuilding of the unit. Also, I plan to do the passenger side light, too.

In the final "analysis", the Evap-O-Rust did a great job cutting through the rust. It wasn't able to get down into the pits, but I think it would have if I had left it in the solution for a couple of days longer. You may be able to see the difference between the straight out of the solution look and the look after polishing. When the metal comes out of the tank, it has a dull gray look to it. I used the Dremel and a high number (light grit) wheel and polished the gray off. It would now be ready for primer, if I wasn't going to remove the bracket and replace the bolts. If I do that soon, I should be able to avoid surface rusting. If some does show up, then I'll polish it again and then prime. See you then....

Subscribe to:

Posts (Atom)